8 ROBOT Construction Rules (R)

The rules listed below explicitly address legal parts and materials and how those parts and materials may be used on a REEFSCAPE

There are many reasons for the structure of the rules, including safety, reliability, parity, creation of a reasonable design challenge, adherence to professional standards, impact on the competition, and compatibility with the Kit of Parts (

Another intent of these rules is to have all energy sources and active actuation systems on the

Many rules in this section reference Commercial-Off-The-Shelf (

Example 1: A team orders 2

Example 2: A team obtains openly available blueprints of a drive module commonly available from Wheels-R-Us Inc. and has local machine shop “We-Make-It, Inc.” manufacture a copy of the part for them. The produced part is not a

Example 3: A team obtains openly available design drawings from a professional publication during the pre-season and uses them to fabricate a gearbox for their

Example 4: A

Example 5: A team has a

Example 6: A team has a

A

A. has a Federal Tax Identification number. In cases where the

B. is not a “wholly owned subsidiary” of a FIRST Robotics Competition team or collection of teams. While there may be some individuals affiliated with both a team and the

C. should maintain sufficient stock or production capability so they are able to ship any general (i.e., non-FIRST unique) product within 5 business days of receiving a valid purchase request. It is recognized that certain unusual circumstances (such as such as a global supply chain disruption and/or 1,000 FIRST teams all ordering the same part at once from the same

For example, a

D. makes their products available to all FIRST Robotics Competition teams. A

The intent of this definition is to be as inclusive as possible to permit access to all legitimate sources, while preventing ad hoc organizations from providing special-purpose products to a limited subset of teams in an attempt to circumvent the cost accounting rules.

FIRST desires to permit teams to have the broadest choice of legitimate sources possible, and to obtain

Ideally, chosen

A FABRICATED ITEM is any

Note that it is possible for an item (typically raw materials) to be neither

Teams may be asked to provide documentation proving the legality of non-REEFSCAPE

Some of these rules make use of English unit requirements for parts. If your team has a question about a metric-equivalent part’s legality, please e-mail your question to the FIRST Robotics Competition Kit of Parts team at frcparts@firstinspires.org for an official ruling. To seek approval for alternate devices for inclusion in future FIRST Robotics Competition seasons, please contact the Kit of Parts team at frcparts@firstinspires.org with item specifications.

Teams should acknowledge the support provided by the corporate sponsors and mentors with an appropriate display of their school and sponsors names and/or logos (or the name of the supporting youth organization, if appropriate).

FIRST Robotics Competition can be a full-contact competition and may include rigorous game play. While the rules aim to limit severe damage to

8.1 General ROBOT Design

R101 *ROBOT PERIMETER must be fixed.

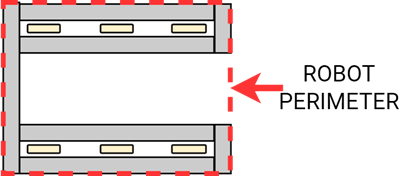

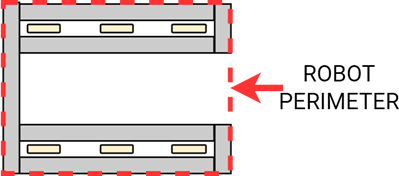

The

To determine the

Example: A

Figure 8‑1

R102 *STARTING CONFIGURATION – no overhang.

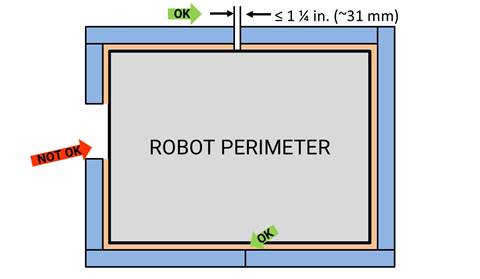

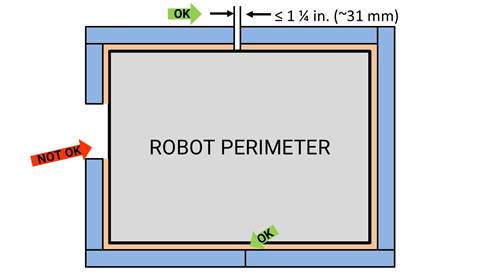

In the STARTING CONFIGURATION (the physical configuration in which a

If a

The allowance for minor protrusions in this rule is intended to allow protrusions that are both minor in extension from the

If a

R103 *ROBOT weight limit.

The

For the purposes of determining compliance with the weight limitations, the following items are excluded:

A.

B.

C. tags used for location detection systems if provided by the event.

R104 STARTING CONFIGURATION – max size.

A

Be sure to consider the size of the

Note that rules contained in section 8.4

R105 ROBOT extension limit.

Teams should expect to have to demonstrate a

See section 7.4.3

8.2 ROBOT Safety & Damage Prevention

R201 *No digging into carpet.

Traction devices must not have surface features that could damage the

R202 *No exposed sharp edges.

Protrusions from the

R203 *General safety.

Examples of items that will violate this rule include (but are not limited to):

A. shields, curtains, or any other devices or materials designed or used to obstruct or limit the vision of any DRIVE TEAM members and/or interfere with their ability to safely

B. speakers, sirens, air horns, or other audio devices that generate sound at a level sufficient to be a distraction,

C. any devices or decorations specifically intended to jam or interfere with the remote sensing capabilities of another

D. exposed lasers other than Class I,

E. flammable gasses,

F. any device intended to produce flames or pyrotechnics,

G. hydraulic fluids or hydraulic items,

H. switches or contacts containing liquid mercury,

I. circuitry used to create voltages in excess of 24 Volts,

J. any ballast not secured sufficiently, including loose ballast e.g. sand, ball bearings, etc., such that it may become loose during a

K. exposed, untreated hazardous materials (e.g. lead weights) used on the

L. tire sealant, and

M. high intensity light sources used on the

R204 *Leave SCORING ELEMENTS at the FIELD.

Teams are encouraged to consider G501 when developing their

R205 *Don’t contaminate the FIELD.

Lubricants may be used only to reduce friction within the

R206 *Don’t damage SCORING ELEMENTS.

SCORING ELEMENTS are expected to undergo a reasonable amount of wear and tear as they are handled by

8.3 Budget Constraints & Fabrication Schedule

R301 *Individual item cost limit.

No individual, non-KOP item or software shall have a Fair Market Value (FMV) that exceeds $600 USD. The total cost of

Teams should be ready to show

The Analog Devices IMU

The FMV of a

The FMV of

The FMV of FABRICATED parts is the value of the material and/or labor, except for labor provided by team members (including sponsor employees who are members of the team), members of other teams, and/or event provided machine shops. Material costs are accounted for as the cost of any purchasable quantity that can be used to make the individual part (i.e. the purchasable raw material is larger than the FABRICATED part).

Example 1: A team orders a custom bracket made by a company to the team's specification. The company’s material cost and normally charged labor rate apply.

Example 2: A team receives a donated sensor. The company would normally sell this item for $450 USD, which is therefore its FMV.

Example 3: A team purchases titanium tube stock for $400 USD and has it machined by a local machine shop. The machine shop is not considered a team sponsor but donates 2 hours of expended labor anyway. The team must include the estimated normal cost of the labor as if it were paid to the machine shop and add it to the $400 USD.

Example 4: A team purchases titanium tube stock for $400 USD and has it machined by a local machine shop that is a recognized sponsor of the team. If the machinists are considered members of the team, their labor costs do not apply. The total applicable cost for the part would be $400 USD.

It is in the best interests of the teams and FIRST to form relationships with as many organizations as possible. Recognizing supporting companies as sponsors of, and members in, the team is encouraged, even if the involvement of the sponsor is solely through the donation of fabrication labor.

Example 5: A team purchases titanium tube stock for $400 USD and has it machined by another team. The total applicable cost for the part would be $400 USD.

Example 6: A team purchases a widget at a garage sale or online auction for $300, but it’s available for sale from a

If a

If the modules are designed to assemble into a single configuration, and the assembly is functional in only that configuration, then the total cost of the complete assembly including all modules must fit within the price constraints defined in this rule.

In summary, if a

Example 7:

Example 8:

Example 9:

R302 *MAJOR MECHANISM, from this year only.

MAJOR

Neither this rule nor the language in this blue box define specific thresholds for how much of a MAJOR

Attempts to exploit loopholes in the definition of MAJOR

A. Pre-assembling significant portions of a MAJOR

B. Removing a small

R303 *Create new designs and software, unless they’re public.

Example 1: A team realizes that the transmission designed and built in the fall perfectly fits their need for a transmission to drive the

Example 2: A team developed an omni-directional drive system for the 2019 competition. In July 2019 they refined and improved the

Example 3: The same team decides to use LabVIEW as their software environment for REEFSCAPE. Following Kickoff, they use the previously developed C++ code as a reference for the algorithms and calculations required to implement their omni-directional

Example 4: A different team develops a similar solution during the fall and plans to use the developed software on their competition

Example 5: A team develops a transmission prior to Kickoff. After completing the project, they publish the CAD files on a generally accessible public forum and make them available to all teams. Because they have made the design publicly available before Kickoff, they can use the design to create an identical transmission, fabricated after Kickoff, for use on their REEFSCAPE

R304 *During an event, only work during pit hours.

During an event a team is attending (regardless of whether the team is physically at the event location), the team may neither work on nor practice with their

A. OPERATOR CONSOLES,

B.

C. software development, and

D. charging batteries.

For the purposes of this rule, official events begin as follows:

- Regionals, District Championships, and FIRST Championship: at the start of the first designated load-in period, according to the Public Schedule. If the Public Schedule is not available or there is no designated load-in period, the events begin at 4pm on the day prior to pits opening.

- District Events: when pits open

Examples of activity prohibited by this rule include:

A. working on the

B. working on

C. running a 3D printer or other automated manufacturing process overnight producing

Note that E107 and E401 impose additional restrictions on work done on the

This rule is intended to increase equity between teams with significant travel to an event and those nearby (close teams would otherwise have an advantage by being able to work on their

8.4 BUMPER Rules

A

A

All dimensions specified in this section are nominal and will be measured during inspection with a tolerance of ¼ in. (~6 mm) unless otherwise specified. This means that maximums specified have a tolerance of + ¼ in. and minimums specified have a tolerance of – ¼ in. Teams are encouraged to design to the nominal dimension and reserve the tolerance for unexpected deviation such as manufacturing error or tolerance stack-up.

R401 *BUMPERS all around.

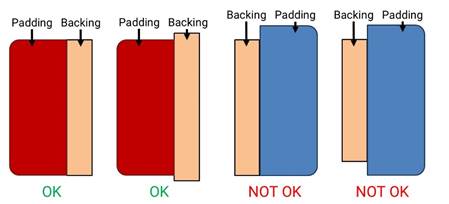

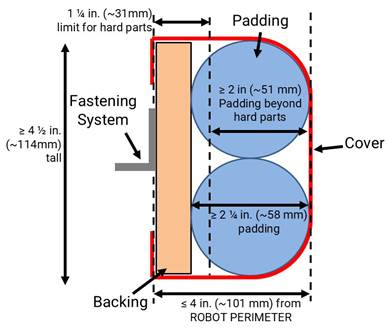

R402 *BUMPER construction.

A. Padding – A minimum of 2 ¼ in. (~58 mm) depth of foam padding, at least 4 ½ in. (~114 mm) tall consisting of solid blocks, sheets, or stacked rods of one or more of the following materials:

i. Pool noodles (hollow or solid) or backer rod

ii. Solid polyethylene closed cell foam with density between 1.5 and 3 lb./ft.3 (~24 to 48 kg/m3)

iii. Solid EVA closed cell foam with density between 2 and 6 lb./ft.3 (~32 to 96 kg/m3)

iv. Foam floor tiles

Multiple types, shapes, and/or layers of foam may be used within a single

Teams should be prepared to provide information about the padding material used in their

B.

Backing – A backer at least 4 ½ in. (~115 mm) tall which supports the padding (i.e. padding is not cantilevered other than in corners) and facilitates installation and removal of the

C.

Cover – Fabric (as noted in G411) which covers all outward, upward and downward facing surfaces such that no padding is exposed to interaction with the

D.

Fastening System –

The

R403 *BUMPER extension limit.

R404 *BUMPERS must be soft.

Hard parts of

Hard parts include any items which are likely to cause damage to the fabric or padding of other

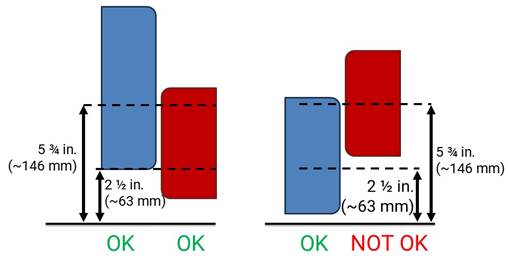

R405 *BUMPERS interact with BUMPERS.

Padding (per R402-A) supported by backing (per R402-B) must entirely fill the

This measurement is intended to be made as if the

Example 1: A

Example 2: A

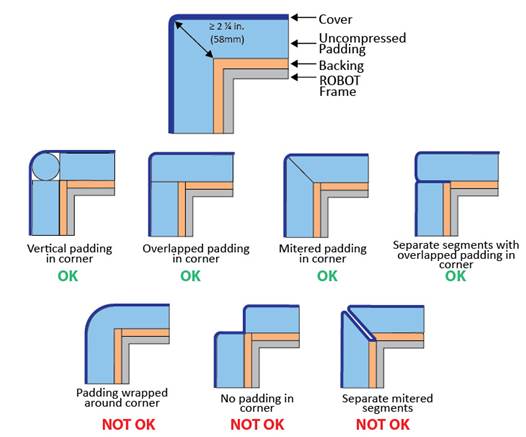

R406 *Fill BUMPER corners.

Corner joints between

Examples that do not meet the requirements of R406:

A. Foam cylinders or sheets bent around a sharp corner (less than 135°) are considered compressed.

B. Separate

R407 *BUMPERS shouldn’t be wedges.

Examples of

A.

B.

C.

D.

R408 *Weight limit with BUMPERS.

The total weight of the

R410 *BUMPERS must come off.

As a guideline,

R411 *BUMPERS indicate your ALLIANCE.

Each

A. those required per R412,

B. hook-and-loop tape, snap fasteners, or functional equivalents backed by the hard parts of the

C. solid white FIRST logos between 4¾ in. (~121 mm) and 5¼ in. wide (~133 mm) (i.e. comparable to those available in the REEFSCAPE Virtual Kit), and

D. narrow areas of underlying fabric exposed at seams, corners, or folds.

R412 *Team number on BUMPERS.

Team numbers must be displayed and positioned on the

A. consist of only white Arabic numerals at least 3 ¾ in. (~96 mm) high, at least ½ in. (~13 mm) in stroke width,

The ½ in. (~13 mm) stroke width requirement applies to the majority of the stroke. Font elements less than ½ in. (~13 mm) such as serifs, rounded edges, small hairlines or gaps, etc. are permitted as long as the majority of the stroke meets the sizing requirement and the numbers are unambiguous.

B. must not wrap around sharp corners (less than 135°) of the

C. must not split individual digits such that the team number is ambiguous, and

As a guideline, spacing between digits or groups of digits which exceeds ~4 in. (~101 mm) may be ambiguous.

D. may not substitute logos or icons for numerals.

There is no prohibition against splitting team numbers onto different sections of

This marking is intended to display the team number only, not to intentionally change the surface characteristics of the

8.5 Motors & Actuators

R501 *Allowable motors.

The only motors and actuators permitted include the following (in any quantity):

| Motor Name | Part Numbers Available | Part Numbers Available |

|---|---|---|

| AndyMark 9015 | am-0912 | AndyMark 9015 |

| AndyMark NeveRest | am-3104 | |

| AndyMark PG | am-2161 (alt. PN am-2765) | am-2194 (alt. PN am-2766) |

| AndyMark RedLine Motor | am-3775 | am-3775a |

| AndyMark Snow Blower Motor | am-2235 | am-2235a |

| Banebots | am-3830 M7-RS775-18 RS775WC-8514 | M5 – RS550-12 RS550VC-7527 RS550 |

| CIM | FR801-001 M4-R0062-12 AM802-001A 217-2000 PM25R-44F-1005 | PM25R-45F-1004 PM25R-45F-1003 PMR25R-45F-1003 PMR25R-44F-1005 am-0255 |

| CTR Electronics Minion | 24-777378 | WCP-1691 |

| CTR Electronics/VEX Robotics Falcon 500 | 217-6515 am-6515 | 19-708850 am-6515_Short |

| Current/former KOP | Denso AE235100-0160 Denso 5-163800-RC1 Denso 262100-3030 | Denso 262100-3040 Bosch 6 004 RA3 194-06 Johnson Electric JE-PLG-149 Johnson Electric JE-PLG-410 |

| Nidec Dynamo BLDC Motor | am-3740 | DM3012-1063 |

| Playing with Fusion Venom | BDC-10001 | |

| REV Robotics HD Hex | REV-41-1291 | |

| REV Robotics NEO Brushless | REV-21-1650 (v1.0 or v1.1) | am-4258 am-4258a |

| REV Robotics NEO 550 | REV-21-1651 | am-4259 |

| REV Robotics NEO Vortex | REV-21-1652 | am-5275 |

| VEX BAG | 217-3351 | |

| VEX Mini-CIM | 217-3371 | |

| West Coast Products Kraken x44 | WCP-0941 | |

| West Coast Products Kraken x60 | WCP-0940 | am-5274 |

| West Coast Products RS775 Pro | 217-4347 | |

| Fans, no greater than 120mm (nominal) size and rated electrical input power no greater than 10 watts (W) continuous | Fans, no greater than 120mm (nominal) size and rated electrical input power no greater than 10 watts (W) continuous | Fans, no greater than 120mm (nominal) size and rated electrical input power no greater than 10 watts (W) continuous |

| Hard drive motors part of a legal COTS | Hard drive motors part of a legal COTS | Hard drive motors part of a legal COTS |

| Factory installed vibration and autofocus motors resident in COTS | Factory installed vibration and autofocus motors resident in COTS | Factory installed vibration and autofocus motors resident in COTS |

| PWM COTS COTS | PWM COTS COTS | PWM COTS COTS |

| Motors integral to a COTS | Motors integral to a COTS | Motors integral to a COTS |

| 1 compressor compliant with R806 and used to compress air for the ROBOT | 1 compressor compliant with R806 and used to compress air for the ROBOT | 1 compressor compliant with R806 and used to compress air for the ROBOT |

COTS | COTS | COTS |

For servos, note that the roboRIO is limited to a max current output of 2.2A on the 6V rail (12.4W of electrical input power). Teams should make sure that their total servo power usage remains below this limit at all times.

Servo mechanical output power is approximated by the following formula (using 6V data reported by manufacturer): Mechanical Output Power (in W) = 0.25 x (Stall Torque in N-m) x (No Load Speed in rad/s). This calculator from the FIRST Tech Challenge documentation can be used to help calculate output power from inputs of various units.

Given the extensive amount of motors allowed on the

AndyMark PG Gearmotors are sold with labeling based on the entire assembly. Assemblies labeled am-3651 through am-3656 contain legal motors specified in Table 8‑1. These motors may be used with or without the provided gearbox.

R502 *Only 4 propulsion motors.

A

Examples that are not considered propulsion motors include:

A. motors that primarily alter the alignment of a wheel in contact with the

B. motors that run

C. motors that change the speed of the drive wheels using a shifting

R503 *Don’t modify motors (mostly).

The integral mechanical and electrical system of any motor must not be modified. Motors, servos, and electric solenoids used on the

A. The mounting brackets and/or output shaft/interface may be modified to facilitate the physical connection of the motor to the

B. The electrical leads may be trimmed to length as necessary and connectors or splices to additional wiring may be added.

C. The locking

D. The connector housings on

E. Servos may be modified as specified by the manufacturer (e.g. re-programming or modification for

F. The wiring harness of the Nidec Dynamo BLDC Motor may be modified as documented by FIRST in Nidec Dynamo BLDC Motor with Controller.

G. Minimal labeling may be applied to indicate device purpose, connectivity, functional performance, etc.

H. Any number of #10-32 plug screws may be removed from the Falcon 500 and the Kraken X60.

I. Insulation may be applied to electrical terminals.

J. Repairs, provided the original performance and specifications are unchanged.

K. Maintenance recommended by the manufacturer.

The intent of this rule is to allow teams to modify mounting tabs and the like, not to gain a weight reduction by potentially compromising the structural integrity of any motor.

R504 *Power (most) actuators off of approved devices.

With the exception of servos, fans, or motors integral to sensors of

A. motor controllers:

a. DMC 60/DMC 60c Motor Controller (P/N 410-334-1, 410-334-2),

b. Jaguar Motor Controller (P/N MDL-BDC, MDL-BDC24, and 217-3367) connected to PWM only,

c. Koors40 Motor Controller (P/N am-5600),

d. Nidec Dynamo, BLDC Motor with Controller to

e. SD540 Motor Controller (P/N SD540x1, SD540x2, SD540x4, SD540Bx1, SD540Bx2, SD540Bx4, SD540C),

f. Spark Flex Motor Controller (P/N REV-11-2159, am-5276)

g. Spark Motor Controller (P/N REV-11-1200, am-4260),

h. Spark MAX Motor Controller (P/N REV-11-2158, am-4261),

i. Talon FX Motor Controller (P/N 217-6515, 19-708850, am-6515, am-6515_Short, WCP-0940, WCP-0941) for controlling integral Falcon 500, Kraken X60, Kraken X44 only,

j. Talon FXS Motor Controller (P/N 24-708883, WCP-1692)

k. Talon Motor Controller (P/N CTRE_Talon, CTRE_Talon_SR, and am-2195),

l. Talon SRX Motor Controller (P/N 217-8080, am-2854, 14-838288),

m. Thrifty Nova (P/N TTB-0100),

n. Venom Motor with Controller (P/N BDC-10001) for controlling integral motor only,

o. Victor 884 Motor Controller (P/N VICTOR-884-12/12),

p. Victor 888 Motor Controller (P/N 217-2769),

q. Victor SP Motor Controller (P/N 217-9090, am-2855, 14-868380), and

B. relay modules:

a. Spike H-Bridge Relay (P/N 217-0220 and SPIKE-RELAY-H),

b. Automation Direct Relay (P/N AD-SSR6M12-DC-200D, AD-SSRM6M25-DC-200D, AD-SSR6M40-DC-200D), and

c. Power Distribution Hub (

C. pneumatics controllers:

a. Pneumatics

b. Pneumatic Hub (P/N REV-11-1852).

D. servo controllers:

a. Servo Hub (P/N REV-11-1855)

Note: The Automation Direct Relays are single directional. Per R504 they may not be wired together in an attempt to provide bi-directional

R505 *Don’t overload controllers.

Each power regulating device may

| Electrical Load | Motor Controller | Relay Module | Pneumatics Controller |

|---|---|---|---|

| AndyMark RedLine Motor Banebots CIM CTR Electronics Minion REV Robotics NEO Brushless REV Robotics NEO 550 REV Robotics NEO Vortex VEX Mini-CIM WCP RS775 Pro | Yes | No | No |

| AndyMark 9015 VEXpro BAG | Yes (up to 2 per controller) | No | No |

| AndyMark PG KOP | Yes (up to 2 per controller) | Yes | No |

| Linear Actuator | Yes (20A breaker max) | Yes (20A breaker max) | No |

| CTR Electronics/VEX Falcon 500 Nidec Dynamo BLDC Motor w/ Controller Playing With Fusion Venom WCP Kraken X44 WCP Kraken X60 | Yes (integrated controller only) | No | No |

| Compressor | No | Yes | Yes |

| Pneumatic Solenoid Valves | No | Yes (multiple) | Yes (1 per channel) |

| Electric Solenoids | Yes (multiple) | Yes (multiple) | Yes (1 per channel) |

| CUSTOM CIRCUITS | Yes (multiple) | Yes (multiple) | Yes (multiple) |

R506 *Control servos safely.

Servos must be connected to, and only to, 1 of the following:

A. PWM ports on the roboRIO,

B. PWM ports on a WCP Spartan Sensor Board (P/N WCP-0045),

C. REV Robotics Servo Power Module (P/N REV-11-1144),

D. REV Robotics Servo Hub (P/N REV-11-1855)

8.6 Power Distribution

In order to maintain safety, the rules in this section apply at all times while at the event, not just while the

R601 *Battery limit – everyone has the same power.

The only legal source of electrical energy for the

A. Nominal voltage: 12V

B. Nominal capacity at 20-hour discharge rate: minimum 17Ah, maximum 18.2Ah

C. Shape: Rectangular

D. Nominal Dimensions: 7.1 in. x 3 in. x 6.6 in., +/- .1 in. for each dimension (~ 180 mm x 76mm x 168 mm, +/- 2.5 mm for each dimension)

E. Nominal weight: 11lbs. to 14.5 lbs. (~5 kg. to 6.5 kg.)

F. Terminals: Nut and bolt style

"Nut and bolt style" refers to any style battery terminal where the connector is secured to the battery using a threaded fastener.

Examples of batteries which meet these criteria include:

A. Enersys (P/N NP18-12, NP18-12B, NP18-12BFR),

B. MK Battery (P/N ES17-12),

C. Battery Mart (P/N SLA-12V18),

D. Sigma (P/N SP12-18),

E. Universal Battery (P/N UB12180),

F. Power Patrol (P/N SLA1116),

G. Werker Battery (P/N WKA12-18NB),

H. Power Sonic (P/N PS-12180NB),

I. Yuasa (P/N NP18-12B),

J. Panasonic (P/N LC-RD-1217),

K. Interstate Batteries (P/N BSL1116), and

L. Duracell Ultra Battery (P/N DURA12-18NB).

Teams should be aware that they may be asked to provide documentation of the specifications of any battery not listed above.

Batteries should be charged in accordance with manufacturer’s specification. (Please see the FIRST Safety Manual for additional information.)

R602 *Other batteries for cameras or computers only.

A. securely fastened to the

B. connected only using unmodified

C. charged according to manufacturer recommendations.

A

R603 *Charge batteries with safe connectors.

Any battery charger used to charge a

R604 *Charge batteries at a safe rate.

Any battery charger used to charge a

R605 *Batteries are not ballast.

No batteries other than those allowed per R601 and R602 are allowed on the

For example, teams may not use additional batteries as extra weight on their

R606 *Secure the battery.

The

R607 *Insulate battery connections.

Each electrical terminal on the

R608 *Limit non-battery energy.

Non-electrical sources of energy used by the

A. compressed air stored in the pneumatic system that has been charged in compliance with R806 and R807,

B. a change in the altitude of the

C. storage achieved by deformation of

D. closed-loop

E. air-filled (pneumatic) wheels.

R609 *Connect main power safely.

The following devices shall be connected with 6 AWG (7 SWG or 16 mm2) copper wire or larger as shown in Figure 8‑9:

A. 1

B. a single pair of Anderson Power Products (or APP) 2-pole SB type connectors,

C. the 1 main 120-Amp (120A) surface mount circuit breaker (Cooper Bussman P/N CB185-120, CB185F-120, CB285-120 CB285F-120, CB285120F or Optifuse P/N 153120, 253120), and

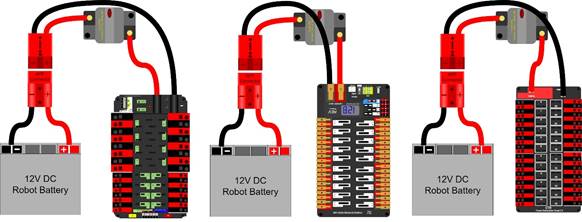

D. the 1 power distribution device (CTR Electronics Power Distribution Panel,

No additional devices or modifications shall be permitted with the following exceptions:

E. Monitoring circuitry permitted by R625

F. SB-50 to SB-120 adapters, provided they have been presented for Inspection.

“SB type” refers to SB type only (e.g. SB-50, SB-120, etc.), not SBS or any other part type beginning with SB. All batteries supplied by FIRST (such as Spare Parts and international batteries) will have a red or pink SB50 connector installed which may not be removed.

The pink connectors included in the

R610 *1 breaker per circuit.

All circuits, with the exceptions of those listed in R615 and R617, must connect to, and have power sourced solely by, a single protected 12VDC WAGO connector pair (i.e. the load terminals, as shown in Figure 8‑9) of the

R611 *The ROBOT frame is not a wire.

All wiring and electrical devices shall be electrically isolated from the

Compliance with this rule is checked by observing a >120Ω resistance between either the (+) or (-) post within the APP connector that is attached to the

All legal motor controllers with metal cases are electrically isolated. They may be mounted directly to

Note that some cameras, decorative lights, and sensors (e.g. some encoders, some IR sensors, etc.) have grounded enclosures or are manufactured with conductive plastics. These devices must be electrically isolated from the

R612 *Must be able to turn ROBOT on and off safely.

The 120A circuit breaker must be quickly and safely accessible from the exterior of the

Examples considered not “quickly and safely accessible” include breakers covered by an access panel or door, or mounted on, underneath or immediately adjacent to moving

It is strongly recommended that the 120A circuit breaker location be clearly and obviously labeled so it can be easily found by

While the main breaker must be accessible, consider positioning or shielding it such that it’s protected from accidental actuation (e.g. it’s unlikely to be hit by a SCORING ELEMENT during game play).

R613 *Electrical system must be inspectable.

The

“Visible for inspection” does not require that the items be visible when the

R614 *No high voltage allowed.

Any active electrical item that is not an actuator (specified in R501) or core

R615 *Power roboRIO as specified.

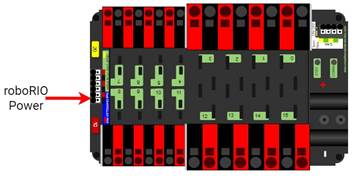

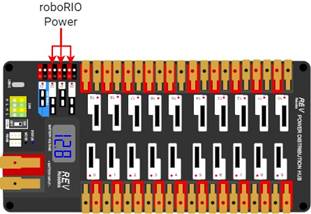

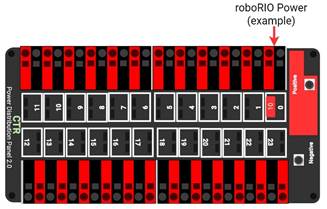

The roboRIO power input must be connected to either:

A. the dedicated supply terminals on the

B. the terminals of 1 of the non-switchable fused channels on the

C. directly to the terminals of any single channel on the

R616 *Power radio as specified – Part 1.

The wireless bridge (radio) power must be supplied by either:

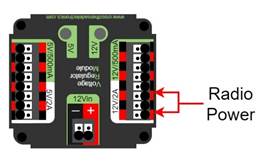

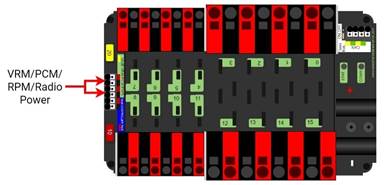

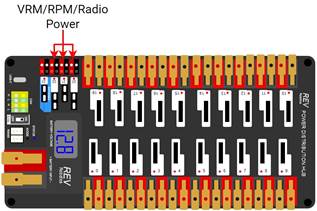

A. the 12V 2A output of a CTR Electronics Voltage Regulator Module (

B. using an Ethernet cable between a REV Radio Power Module (

C. directly from the

Note that this prohibits using any other active POE injector device to power the radio but does not prohibit using any PASSIVE CONDUCTORS to inject the

The use of a

R617 *Power radio as specified – Part 2.

The device supplying power to the wireless bridge per R616 must be connected to either:

A. the designated supply terminals at the end of the

B. the terminals of the non-switchable fused channels on the

C. directly to the terminals of any channel on the

Please reference How to Wire an FRC

R618 *Use PDP/PDP2.

0/

If multi-point distribution of circuit power is needed (e.g. to provide power to multiple

R619 *Only use specified circuit breakers in PDP/PDP2.

0/

A. Snap Action VB3-A Series or AT2-A, terminal style F57, 40A rating or lower,

B. Snap Action MX5-A or MX5-L Series, 40A rating or lower,

C. REV Robotics ATO auto-resetting breakers 40A rating or lower,

D. Any ATM circuit breaker with value less than or equal to the fuses permitted per R620.

R620 *Only use specified fuses in PDP/PDP2.

0/

A. for the

B. for the

C. for the

Note that these fuses must be pressed very firmly to seat properly. Improper seating can cause a device to reboot upon impact.

R621 *Protect circuits with appropriate circuit breakers.

Each

Branch | Circuit Breaker/Fuse Value | Quantity Allowed Per Breaker |

|---|---|---|

| Motor Controller | Up to 40A | 1 |

| CUSTOM CIRCUIT | Up to 40A | No limit |

| Automation Direct Relay 40A (6M40) | Up to 40A | 1 |

| Fans permitted per R501 and not already part of COTS | Up to 20A | No limit |

| Spike Relay Module | Up to 20A | 1 |

| Automation Direct Relay 25A (6M25) | Up to 20A | 1 |

PCM PH | Up to 20A | 1 |

| Servo Power Module/Servo Hub | Up to 20A | 1 |

| Additional VRM PCM PH | Up to 20A | 3 total |

| Automation Direct Relay 12A (6M12) | Up to 10A | 1 |

This rule does not prohibit the use of smaller value breakers in the

Fans permitted per R501 may also be included within CUSTOM CIRCUITS.

R622 *Use appropriately sized wire.

All circuits shall be wired with appropriately sized insulated copper wire (SIGNAL LEVEL cables don’t have to be copper):

| Application | Minimum Wire Size |

|---|---|

| 31 – 40A breaker protected circuit | 12 AWG (13 SWG or 4 mm2) |

| 21 – 30A breaker protected circuit | 14 AWG (16 SWG or 2.5 mm2) |

| 6 – 20A breaker protected circuit | 18 AWG (19 SWG or 1 mm2) |

| 11-20A fuse protected circuit | |

| Between the PDP VRM RPM PCM PH | |

| Compressor outputs from the PCM PH | |

| Between the PDH PCM PH | |

| Between the PDP PDH | 22 AWG (22 SWG or 0.5 mm2) |

| Between the PDH VRM RPM | |

| Kraken x60 Powerpole Adapter protected circuit | |

| ≤5A breaker protected circuit | |

| ≤10A fuse protected circuit | |

VRM | 24 AWG (24 SWG or .25 mm2) |

| roboRIO PWM port outputs | 26 AWG (27 SWG or 0.14 mm2) |

| SIGNAL LEVEL circuits (i.e. circuits which draw ≤1A continuous PCM PH VRM RPM | 28 AWG (29 SWG or .08 mm2) |

Wires that are recommended by the device manufacturer or originally attached to legal devices are considered part of the device and by default legal. Such wires are exempt from this rule, provided they are powered by the smallest value fuse or breaker which permits proper device operation.

In order to show compliance with these rules, teams should use wire with clearly labeled sizes if possible. If unlabeled wiring is used, teams should be prepared to demonstrate that the wire used meets the requirements of this rule (e.g. wire samples and evidence that they are the required size).

R623 *Use only appropriate connectors.

Slip rings containing mercury are prohibited per R203.

R624 *Use specified wire colors (mostly).

All non-SIGNAL LEVEL wiring with a constant polarity (i.e., except for outputs of relay modules, motor controllers, or sensors) shall be color-coded along their entire length from the manufacturer as follows:

A. red, yellow, white, brown, or black-with-stripe on the positive (e.g. +24VDC, +12VDC, +5VDC, etc.) connections

B. black or blue for the common or negative side (-) of the connections

Exceptions to this rule include:

C. wires that are originally attached to legal devices and any extensions to these wires using the same color as the manufacturer

D. Ethernet cable used in POE cables

R625 *Don’t modify critical power paths.

CUSTOM CIRCUITS shall not directly alter the power pathways between the

A noise filter may be wired across motor leads or PWM leads. Such filters will not be considered CUSTOM CIRCUITS and violate neither this rule nor R712.

Acceptable signal filters must be fully insulated and must be 1 of the following:

- 1 microfarad (1 µF) or less, non-polarized, capacitor may be applied across the power leads of any motor on your (as close to the actual motor leads as reasonably possible) orROBOT

- a resistor may be used as a shunt load for the PWM signal feeding a servo.control

8.7 Control, Command & Signals System

R701 *Control the ROBOT with a roboRIO.

There are no rules that prohibit co-processors, provided commands originate from the roboRIO to enable and disable all power regulating devices. This includes motor controllers legally wired to the CAN bus.

R702 *Communicate with the ROBOT with the specified radio.

1 Vivid Hosting wireless bridge (P/N: VH-109), that has been configured with the appropriate encryption key for your team number at each event, is the only permitted device for communicating to and from the

R703 *Use specific Ethernet port for roboRIO.

The roboRIO Ethernet port must be connected to the wireless bridge port labeled “RIO” for VH-109 radios or “18-24v POE” for OpenMesh radios (either directly, via a network switch, via an

Note: Placing a switch between the roboRIO and radio may impede the ability for

R704 *Only use allowed ports and bandwidth to communicate with the ROBOT.

Communication between the

A. 7 Mbits/second for Vivid Hosting wireless bridge radios

B. 4 Mbits/second for OpenMesh radios

| Port | Designation | Bi-directional? |

|---|---|---|

| UDP/TCP 1180-1190 | Camera data from the roboRIO to dashboard software when the camera is connected the roboRIO via USB | Yes |

| TCP 1735 | SmartDashboard | Yes |

| UDP 1130 | Dashboard-to-ROBOT control | Yes |

| UDP 1140 | ROBOT-to-Dashboard status data | Yes |

| HTTP 80 | Camera connected via switch on the ROBOT | Yes |

| HTTP 443 | Camera connected via switch on the ROBOT | Yes |

| UDP/TCP 554 | Real-Time Streaming Protocol for h.264 camera streaming | Yes |

| UDP/TCP 1250 | CTRE Diagnostics Server | Yes |

| UDP/TCP 5800-5810 | Team use | Yes |

Teams may use these ports as they wish if they do not employ them as outlined above (i.e. TCP 1180 can be used to pass data back and forth between the

Note that the 4 Mbit limit will be strictly enforced by the wireless bridge.

The

While FIRST makes every effort to provide a wireless environment that allows teams access to a full 4 Mbits/second data rate (with about 100 Kbit used for

R705 *Configure devices for your team number.

The roboRIO,

R706 *Don’t bypass the ARENA network.

All signals must originate from the OPERATOR CONSOLE and be transmitted to the

R707 *Limited wireless allowed.

The only forms of wireless communication that may be used to communicate to, from, or within the

A. those required per R702 and R706

B. tags used for location detection systems if provided by the event

C. RFID or NFC systems used exclusively within the

Devices that employ signals in the visual spectrum (e.g. cameras) and non-RF sensors that don’t receive human-originated commands (e.g. “beam break” sensors or IR sensors on the

R708 *Wireless bridge must be visible.

The wireless bridge must be mounted on the

Teams are encouraged to mount the wireless bridge away from noise generating devices such as motors,

R709 *ROBOTS must have a signal light.

Any

A. mounted on the

B. connected to the “

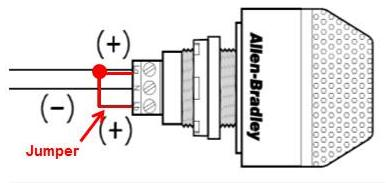

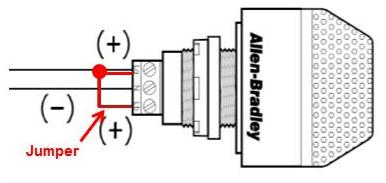

C. if using the 855PB-B12ME522, wired for solid light operation, by placing a jumper between the “La” and “Lb” terminals on the light per Figure 8‑16.

Please see How to Wire an FRC

R710 *Only specified modifications to control system devices permitted.

The

Please note that the

A. User programmable code in the roboRIO may be customized.

B. Motor controllers may be calibrated as described in owner's manuals.

C. Fans may be attached to motor controllers and may be powered from the power input terminals.

D. If powering the compressor, the fuse on a Spike H-Bridge Relay may be replaced with a VB3A-20A Snap-Action circuit breaker.

E. Wires, cables, and signal lines may be connected via the standard connection points provided on the devices.

F. Fasteners (including adhesives) may be used to attach the device to the OPERATOR CONSOLE or

G. Thermal interface material may be used to improve heat conduction.

H. Labeling may be applied to indicate device purpose, connectivity, functional performance, etc.

I. Jumpers may be changed from their default location.

J. Limit switch jumpers may be removed from a Jaguar motor controller and a custom limit switch circuit may be substituted.

K. Device firmware may be updated with manufacturer supplied firmware.

L. Integral wires on motor controllers may be cut, stripped, and/or connectorized.

M. Devices may be repaired, provided the performance and specifications of the device after the repair are identical to those before the repair.

N. The cover may be removed from the Talon SRX or Talon FX data port.

O. Electrical tape may be applied to the aluminum plate inside the wireless bridge.

P. The input terminal cover from the

Q. The roboRIO 2.0 SD card may be replaced with an SD card of any capacity.

S. replacing

T. tape may be applied for debris protection.

Please note that while repairs are permitted, the allowance is independent of any manufacturer’s warranty. Teams make repairs at their own risk and should assume that any warranty or return options are forfeited. Be aware that diagnosing and repairing

For more information about modification O, please see this OM5P-AC Radio Modification article.

R711 *Don’t connect motor outputs to roboRIO.

Neither 12VDC power nor relay module or motor controller outputs shall be directly connected to the roboRIO, with the exception of the designated 12VDC input.

R712 *Control PWM controllers from the roboRIO.

Every relay module (per R504-B), servo controller, and PWM motor controller shall be connected to a corresponding port (relays to Relay ports, servo controllers and PWM controllers to PWM ports) on the roboRIO (either directly or through a WCP Spartan Sensor Board) or via a legal

R713 *Only approved MXP devices can control actuators.

If a motor is controlled via the

A. directly to any PWM

B. via a network of PASSIVE CONDUCTORS used to extend the PWM

C. via 1 approved ACTIVE DEVICE:

a. Kauai Labs navX

b. Kauai Labs navX2

c. RCAL

d. REV Robotics RIOduino

e. REV Robotics Digit Board

f. West Coast Products Spartan Sensor Board

g. Huskie Robotics HUSKIE 2.0 Board

A PASSIVE CONDUCTOR is any device or circuit whose capability is limited to the conduction and/or static regulation of the electrical energy applied to it (e.g. wire, splices, connectors, printed wiring board, etc.).

An ACTIVE DEVICE is any device capable of dynamically controlling and/or converting a source of electrical energy by the application of external electrical stimulus.

The “network of PASSIVE CONDUCTORS” only applies to the

R714 *Control CAN motor controllers from the roboRIO.

Each CAN motor controller must be controlled with enable/disable inputs sourced from the roboRIO and passed via either a PWM (wired per R713) or CAN bus (either directly or daisy-chained via another CAN bus device) signal, but both shall not be wired simultaneously on the same device.

As long as the CAN bus is wired legally so that the heartbeat from the roboRIO is maintained, all closed loop

“Wired directly” includes via any series of PASSIVE CONDUCTORS (i.e. star or hub configurations using only PASSIVE CONDUCTORS are permitted.)

R715 *Control PCM/PH(S) from roboRIO.

Each

R716 *Don’t alter the CAN bus.

No device that interferes with, alters, or blocks communications among the roboRIO and the

Only 1 wire should be inserted into each Weidmuller CAN connector terminal. For documentation on how to wire the CAN bus connections see How to Wire an FRC

R717 *USB to CAN adapter permitted.

Additional CAN bus connections may be added to the roboRIO using the CTR Electronics CANivoreTM (P/N 21-678682, WCP-1522) USB-to-CAN adapter.

Any additional CAN bus added in this manner satisfies the requirements of R714 (i.e. you may connect motor controllers to this additional bus).

8.8 Pneumatic System

In order to maintain safety, the rules in this section apply at all times while at the event, not just while the

R801 *Only use explicitly permitted pneumatic parts.

To satisfy multiple constraints associated with safety, consistency, inspection, and constructive innovation, no pneumatic parts other than those explicitly permitted in this section shall be used on the

R802 *No custom pneumatics and meet minimum pressure ratings.

All pneumatic items must be

A. rated by their manufacturers for pressure of at least 125psi (~862 kPa, 8.6 Bar), or

B. installed downstream of the primary relieving regulator (see R809), and rated for pressure of at least 70psi (~483 kPa, 4.8 Bar)

Any pressure specification such as “working,” “operating,” “maximum,” etc. may be used to satisfy the requirements of this rule.

It is recommended that all pneumatic items be rated by their manufacturers for a working pressure of at least 60 psi (~414 kPa, 4.1 Bar).

R803 *Don’t modify pneumatics.

All pneumatic

A. tubing may be cut,

B. wiring for pneumatic devices may be modified to interface with the

C. assembling and connecting pneumatic

D. removing the mounting

E. labeling applied to indicate device purpose, connectivity, functional performance, etc.

Do not, for example, paint, file, machine, or abrasively remove any part of a pneumatic

R804 *Only use specific pneumatic devices.

The only pneumatic system items permitted on

A. pneumatic pressure vent plug valves functionally equivalent to those provided in the

Examples of acceptable valves include Parker PV609-2 or MV709-2.

B. pressure relief valves functionally equivalent to those provided in the

Examples of acceptable valves include Norgren 16-004-011, 16-004-003 or McMaster-Carr 48435K714.

To be considered functionally equivalent the valve must be preset or adjustable to 125 psi (~862 kPA, 8.6 Bar) and capable of relieving at least 1 scfm (~472 cm3/s).

C. solenoid valves with a maximum ⅛ in. (nominal, ~3 mm) NPT, BSPP, or BSPT port diameter or integrated quick connect ¼ in. (nominal, ~6mm) outside diameter tubing connection,

D. additional pneumatic tubing, with a maximum ¼ in. (nominal, ~6 mm) outside diameter,

E. pressure transducers, pressure gauges, passive flow

F. check and quick exhaust valves, provided that the requirements of R813 are still met.

G. shutoff valves which relieve downstream pressure to atmosphere when closed (may also be known as 3-way or 3-way exhausting valves),

H. pressure regulators with the maximum outlet pressure adjusted to no more than 60 psi (~413 kPa, 4.1 Bar),

I. pneumatic cylinders, pneumatic linear actuators, and rotary actuators,

J. pneumatic storage tanks (with the exception of white Clippard tanks P/N AVT-PP-41),

K. 1 compressor that is compliant with R806,

L. debris or coalescing (water) filters, and

M. Venturi valves (note: the high-pressure side of a Venturi valve is considered a pneumatic device and must follow all pneumatic rules. The vacuum side of a Venturi valve is exempt from the pneumatic rules per “a” in the blue box below).

The following devices are not considered pneumatic devices and are not subject to pneumatic rules (though they must satisfy all other rules):

A. a device that creates a vacuum,

B. closed-loop

C. air-filled (pneumatic) wheels, and

D. pneumatic devices not used as part of a pneumatic system (i.e. used in a way that does not allow them to contain pressurized air)

R805 *If using pneumatics, these parts are required.

If pneumatic

A. 1 FIRST Robotics Competition legal compressor (per R806),

B. a pressure relief valve (per R804-B) connected and calibrated (per R811),

C. a Nason pressure switch (P/N SM-2B-115R/443) and/or REV Robotics Analog Pressure Sensor (P/N REV-11-1107) connected and wired per R812,

D. at least 1 pressure vent plug plumbed (per R813),

E. stored pressure gauge and working pressure gauge (per R810), and

F. 1 primary working pressure regulator (per R808).

R806 *Compressed air from ROBOT compressor only.

Throughout an event, compressed air on the

A

Note: Viair C-series compressors, which have a max working pressure of 120 PSI, are rated for intermittent pressures greater than 125 PSI and therefore meet the requirements of this rule.

R807 *Air storage pressure limit.

Stored air pressure on the

R808 *Working air pressure limit.

Working air pressure (air pressure used to actuate devices) on the

Examples of acceptable valves include Norgren regulator P/N R07-100-RNEA and Monnier P/N 101-3002-1.

R809 *Limited devices at high pressure.

Only the compressor, relief valve, pressure switch, pressure vent plug, pressure gauge, storage tanks, tubing, pressure transducers, filters, and connecting fittings may be in the high-pressure pneumatic circuit upstream from the regulator.

It is recommended that all

R810 *Pressure gauges must be visible.

Pressure gauges must be placed in easily visible locations upstream and downstream of the regulator to display the stored and working pressures, respectively. Pressure gauges must show pressure in psi, kPa, or Bar.

R811 *Relief valve requirements.

The relief valve must be attached directly to the compressor or attached by legal hard fittings (e.g. brass, nylon, etc.) connected to the compressor output port.

Teams are required to check and/or adjust the relief valve to release air at 125 psi (~862 kPa, 7.9 Bar). The valve may or may not have been calibrated prior to being supplied to teams.

Instructions for adjusting the pressure relief valve can be found in the Pneumatics Manual.

R812 *Pressure switch requirements.

The pressure switch must be connected to the high-pressure side of the pneumatic circuit (i.e. prior to the pressure regulator) to sense the stored pressure of the circuit.

It must be either:

A. Nason P/N SM-2B-115R/443 (wired as described) and/or

The 2 wires from the pressure switch must be connected directly to the pressure switch input of the

B. REV Robotics P/N REV-11-1107 (wired as described)

The analog output of the sensor must be connected directly to analog input 0 of the

The REV Robotics Analog Pressure Sensor may only be used with

R813 *Vent plug requirements.

Any pressure vent plug must be:

A. connected to the pneumatic circuit such that, when manually operated, it will vent to the atmosphere to relieve all stored pressure in a reasonable amount of time and

B. placed on the

R814 *Don’t connect solenoid outputs together.

The output air from multiple solenoid valves must not be combined.

Manifolds, shuttle valves, and other devices which do not combine output airflow, even though it may be plumbed into the same device, are not violations of this rule.

8.9 OPERATOR CONSOLE

R901 *Use the specified Driver Station Software.

The

Teams are permitted to use a portable computing device of their choice (laptop computer, tablet, etc.) to host the

R902 *The OPERATOR CONSOLE must have a visible display.

The OPERATOR CONSOLE, the set of

R903 *Connect FMS Ethernet directly to the OPERATOR CONSOLE.

Devices hosting the

Teams are strongly encouraged to use pigtails on the Ethernet port used to connect to the

R904 *OPERATOR CONSOLE physical requirements.

The OPERATOR CONSOLE must not

A. be longer than 5 ft. (~152 cm),

B. be deeper than 1 ft. 2 in. (~35 cm) (excluding any items that are held or worn by the

C. extend more than 6 ft. 6 in. (~198 cm) above the floor, or

D. attach to the

There is a 4 ft. 6 in. (~137 cm) long by 2 in. (nominal) wide strip of hook-and-loop tape (“loop” side) along the center of the

Please note that while there is no hard weight limit, OPERATOR CONSOLES that weigh more than 30 lbs. (~13 kg.) will invite extra scrutiny as they are likely to present unsafe circumstances.

R905 *FIELD wireless only.

Other than the system provided by the

Examples of prohibited wireless systems include, but are not limited to, active wireless network cards and Bluetooth devices. For the case of the FIRST Robotics Competition, a motion sensing input device (e.g. Microsoft Kinect) is not considered wireless communication and is allowed.

R906 *No unsafe OPERATOR CONSOLES.

OPERATOR CONSOLES shall not be made using hazardous materials, be unsafe, cause an unsafe condition, or interfere with other DRIVE TEAMS or the operation of other

R907 *No AC inverters.

OPERATOR CONSOLES must not contain AC inverters.